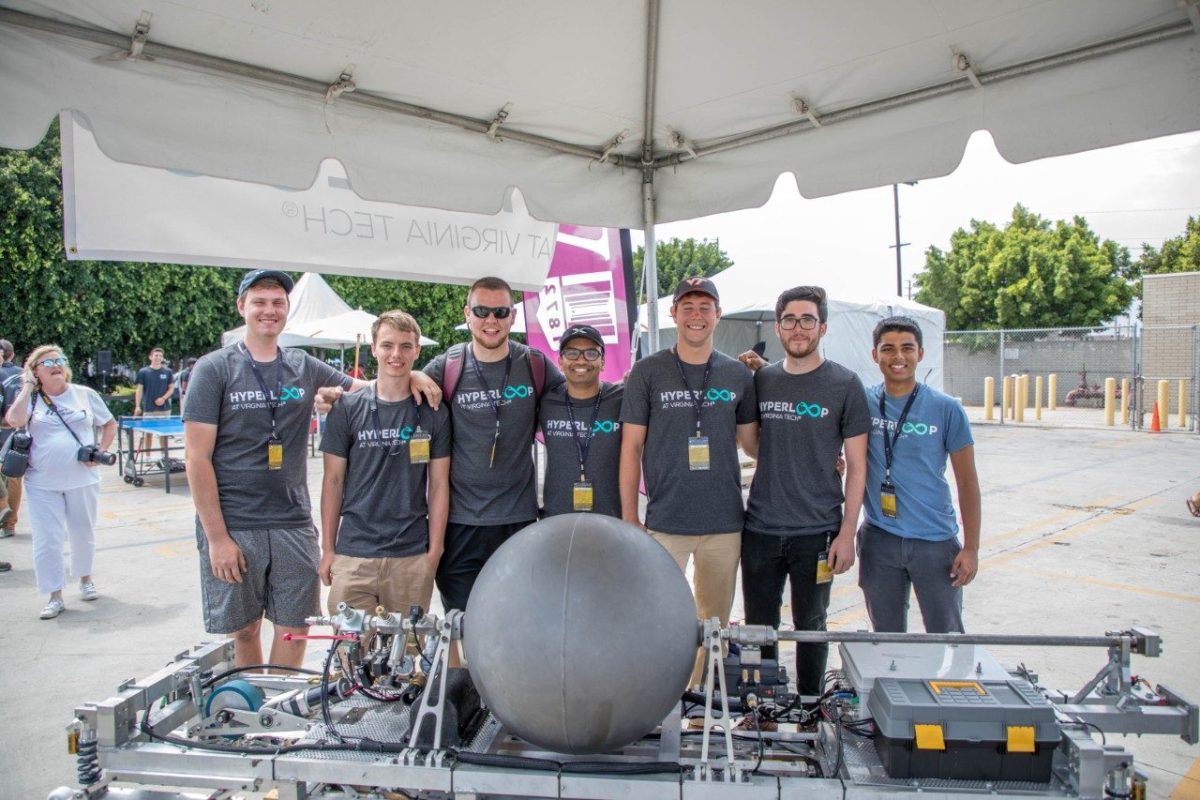

Eleven Virginia Tech undergraduate engineering students ventured to SpaceX in Hawthorne, California, for the innovative aerospace company’s Hyperloop Pod Competition II, the second round of the international competition.

After landing in Los Angeles on Aug. 19, the Hyperloop at Virginia Tech team spent the week modifying and integrating the systems on their pod, called the V17, and completing safety tests. The students also met with SpaceX representatives and toured the company’s campus.

While the team was not selected by SpaceX to be one of the three teams to compete in the external Hyperloop test track on competition day, it did complete many of the prerequisite tests with their pod.

“Our pod is a complex system and with a complex system, there’s a lot of things that could potentially go wrong,” said Bobby Smyth, of Yorktown, Virginia, a senior studying mechanical engineering and mechanical team lead, who has also interned at SpaceX. “Once we completed our final integration of the system, we found that there were a couple of things that we needed to tweak and improve to make sure that everything was working seamlessly.”

During the week leading up to the final competition, the team worked to certify their pod through rounds of preliminary checks, including a structural test, a navigation test, a functional test, propulsion approval, and a vacuum chamber test. The team defended the design of their pod to SpaceX representatives due to the potential safety hazards associated with racing a pod through a near-vacuum chamber at high speeds.

The V17 was designed with speed in mind: the 600-pound pod’s suspension system was topped with a large spherical tank that constituted the pod’s propulsion system. The team estimated that the pod could run upward of 55 mph, fueled by compressed high-pressure nitrogen and aided by a SpaceX-designed pusher on the test track.

While theoretically the pod would have been ready to run on the track, the team ran into complications with the electronics as they integrated the system. The team used quick thinking and multiple trips to home improvement and electrical stores to address issues as they found them.

“Everything is very different when you get down to actual testing than it is on paper,” said Eric Plevy, of Durham, North Carolina, a senior majoring in aerospace engineering who is on Hyperloop at Virginia Tech’s aerospace and propulsion subteam. “You can be good at your individual design task … but it’s going to do no good if you don’t understand how it works relative to the rest of the pod.”

Read the full story and see my photos, feature video, and 360 video via VT News and the College of Engineering website